Alcoholic drink production equipment

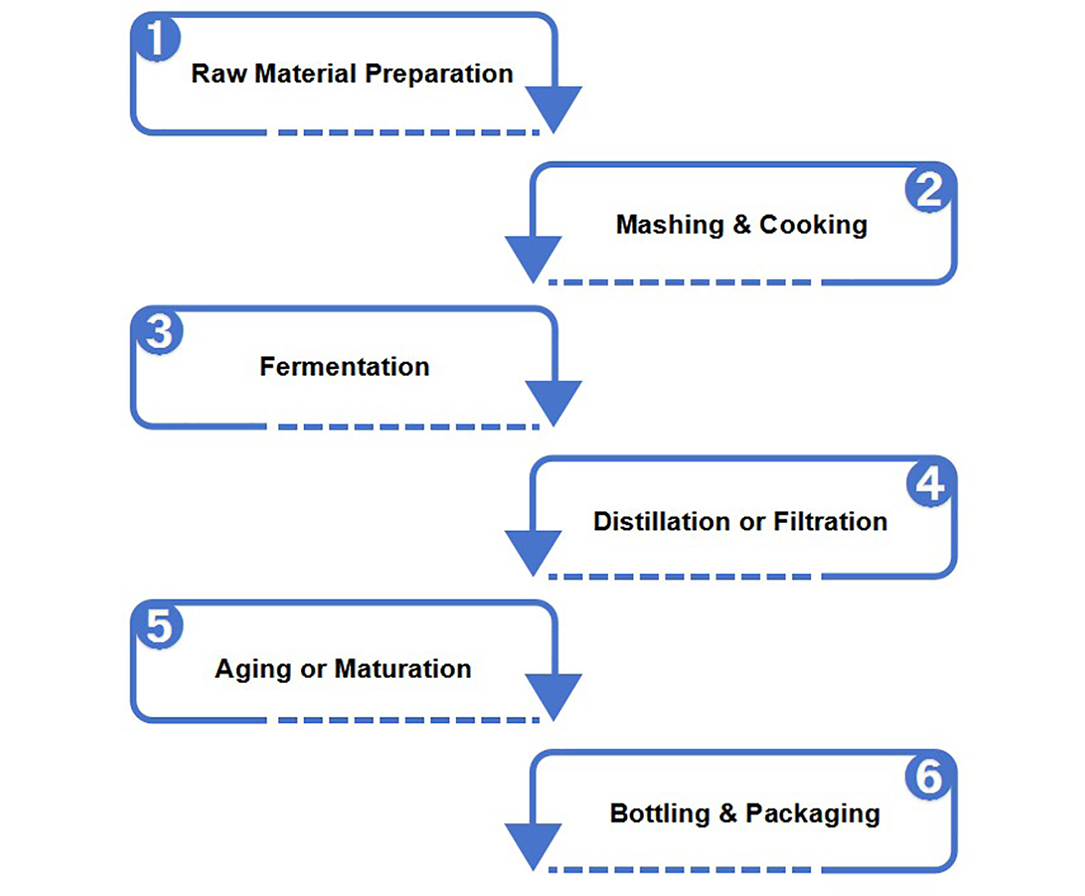

Complete Production Process from Start to Finish

Core System Components & Equipment Overview

Our alcohol production equipment for beverages includes a range of modular, scalable systems:

● Mash Tanks and Cooking Kettles: With agitators and steam heating for grain and malt-based products

● Fermentation Vessels: Insulated tanks with temperature and pressure control, CO₂ blow-off valves, and CIP cleaning systems● Distillation Columns: Copper or stainless steel multi-plate columns for vodka, whiskey, and gin

● Wine Fermenters: Jacketed tanks with variable capacity, floating lids, or submerged cap systems

Filtration Units: DE filters, cross-flow membrane systems, and activated carbon filters for clarity and stability

● Bottling Lines: Gravity fillers, vacuum filling machines, corkers, cappers, and labeling machines with optional nitrogen flushing

● CIP & Utility Systems: Includes steam boilers, chillers, and clean-in-place sanitation for a complete hygienic setup

Every piece of machinery is designed in compliance with international food-grade standards, with customizable specifications for any alcohol type.

Specialized Systems for Microbreweries, Wineries, and Distilleries

● Microbrewery Fermentation and Bottling System: Combines brewhouse units (mash tun, lauter tun, kettle, and whirlpool), fermentation tanks, brite tanks, and compact bottling lines. Ideal for craft beer producers focusing on batch consistency and flavor diversity.

● Wine Production Equipment for Wineries: Includes grape crushers, destemmers, pneumatic presses, stainless steel fermenters, wine clarification systems, and corking machines. Designed to preserve aromatic complexity and color integrity from vineyard to bottle.

● Whiskey and Vodka Distillation Equipment: Utilizes copper pot stills or continuous distillation columns to produce high-purity spirits. Configurations include pre-heaters, dephlegmators, and condensers, ensuring precise flavor retention and ethanol separation.

Each solution supports product-specific features such as carbonation, aging control, or blending precision—perfectly suited for artisanal and commercial-scale operations.

Benefits of Mic Machinery’s Alcohol Systems

Our beverage processing machines for alcohol offer significant competitive advantages:

☑ High output efficiency with low energy consumption and reduced waste

☑ Automated control interfaces with smart PLCs for temperature, pH, and fermentation tracking

☑ Hygienic design with polished interiors, sanitary valves, and sterile fittings

☑ Adaptability for a wide variety of recipes and alcohol content levels

☑ Modular construction that allows gradual capacity upgrades as your business grows☑ Robust engineering that handles continuous operation with minimal downtime

Whether you’re launching a new label or scaling up an existing brand, our systems are built for longevity and return on investment.

Precision and Craftsmanship in Every Detail

Every unit is pressure-tested, calibrated, and factory-run before shipment. The layout of pipework and platforms is optimized for operational ergonomics, space-saving, and easy cleaning. From sensor calibration to piping layout, every technical aspect is engineered for your comfort, efficiency, and food safety compliance.

Long-Term Support and Global Reliability

Mic Machinery provides lifetime service and support to every customer. We offer on-site installation, commissioning, remote diagnostics, operator training, and preventive maintenance plans. Spare parts are available with fast lead times and international shipping. Software updates, line expansions, and custom reconfigurations are offered as your product lines evolve.

Our alcoholic drink production machinery is trusted by breweries, distilleries, and wineries across over 40 countries. With proven durability, international certifications, and continuous innovation, Mic Machinery is your reliable partner in alcohol beverage manufacturing.

- Hot Sauce Filling Production Line

- Lube Oil Production Line

- Olive Oil Production Line

- Perfume Production Line

- Silicone Production Line

- Beer Production Line

- Tube Manufacturing Machine

- Filling Machine Manufacturer

- Visual Inspection Machine

- Bottle Blowing Machine

- Laser Coding Machine

- Aseptic Cold Filling Machine

- Fruit and Vegetable Processing Machinery Manufacturer

- Dairy Products Machinery

- Alcoholic Drink Production Equipment

- Commercial Water Treatment System